by

The Farallones Institute Rural Center and CHP Inter national, Inc. in collaboration with the

Peace Corps Energy Project/ OPTC

|

The Peace Corps Internet Web Site address: http://www.peacecorps.gov Please note the new Peace Corps Mailing Address from July 1998 on is: ICE/ Peace Corps 1111 20th Street N.W. Washington, DC 20526 USA |

Contract #282-1003

August, 1982

Contributors:

Pete Watson

Michael Wilburn.

Ada Jo Mann

Andrew Atkeison

Marsha D. F. Wilburn

Mary Ana Conn

This training manual represents one component of a pilot training program in Blacksmithing/Agricultural Tools undertaken by the Farallones Institute and CHP International, Inc. It has been completed in accordance with the terms of Peace Corps Contract #282-1003.

We believe that our involvement has produced a valuable and adaptable learning tool. However, the manual must continue to be tested, evaluated, and modified in order to reflect changing needs and circumstances. It is our hope that you will contribute to that process, and that you will help make the manual more appropriate and useful during future training programs.

If you have observations or suggestions about the contents, methods, or approach included in the manual, please contact the authors at the Farallones Institute or CHP International, Inc.

We are grateful to the following individuals for their contributions to the development of this manual:

Howard Raik

Ilios Aditya

Leanne Clement

We also thank the many kind people who have contributed by giving us permission to use materials they have developed.

Special thanks are extended to the members of the Farallones community for their continued support, endurance, and patience during the evolution of this project.

Finally, perhaps our most important acknowledgment should go to the Peace Corps trainees who have come to learn and, in turn, to teach. It is with them that we have shared our dreams and values. We hope that the tools and techniques they have chosen will serve the world kindly and well.

This manual is a guide for trainers who are helping Peace Corps Volunteers to acquire basic blacksmithing skills. The training is designed to give Volunteers a knowledge of metals and metalworking that will help them support rural communities in their efforts to produce tools for agriculture and cottage industry.

An equally important goal of Basic Techniques of Blacksmithing is to equip training participants with the skills and knowledge which will help them foster the community development process. Community development is a process that begins when people take an active role in their own education. It is a creative process, challenging members of a group to use their combined talents, resources and ingenuity to identify needs and find appropriate, sustainable ways to meet them. Trainers can contribute to this process by helping others learn from, support and build upon existing blacksmithing technologies. They can help by making training a model of the activity which constitutes community development.

Throughout the training, workshop participants are encouraged to take a full and active role in their own education, and to make decisions that will affect them and the people with whom they work and live. They are urged to cooperate with others, and to identify and use the talents and resources available within the group; they practice skill; that help motivate people, instill within them a sense of self-confidence, and involve them in the process of their own education. The emphasis placed on developing and reinforcing these skills reflects Peace Corps' belief that technical expertise is valuable only when it is applied in balance with other qualities.

This approach to training is based on the principles of non-formal education, and is designed to strike a balance between structured learning and independent discovery. By using the sessions, resources and methods suggested in this program, trainers will provide Volunteers with a working knowledge of blacksmithing, as well as skills for developing that knowledge in a meaningful way.

The program offers training in the development of skills and techniques related to basic blacksmithing, including an attempt to familiarize Peace Corps Volunteers with the capabilities of existing local forges in the production of appropriate agricultural tools. The tool designs and skills are selected to be as consistent as possible with the realities of rural areas in developing countries.

The program is divided into twenty sessions which occur over a six-day period. Each session consists of a series of activities designed to meet specific training objectives. The objectives of each session are interrelated with fundamental themes which illustrate the connection and interdependence between technology and other aspects of community development. The program themes are:

* Development and Transfer of Technical Competence

* Principles and Techniques of Non-Formal Education and Adult Learning

* Methods and Approaches to Problem-Solving

* Development Issues

* Cross-Cultural Perspectives

* The Process of Assessment and Evaluation

The manual is designed to be responsive to a variety of training situations. Modification and adaptation of the materials is encouraged. However, it is essential to the effectiveness of the training to maintain the integrated nature of the sessions by providing an adequate balance of emphasis among the various themes. This will enable participants to build upon and apply new knowledge in a way that is ordered and meaningful within the context of community development.

The following guidelines have been developed as an aid in transforming this manual into an effective, dynamic training program:

Planning and Preparation

There are many steps that need to occur before the training actually begins. These include defining the scope and approach of the training, identifying staff requirements, locating and establishing a site, and gathering necessary resources and materials.

* Defining the scope and approach of the training:

Sessions are designed to accomodate a maximum of twelve participants. If there are more than twelve, some modification of the design of activities will have to occur. The participants should be individuals whose current work in agriculture, rural or community development, or vocational education could be enhanced by a knowledge of basic blacksmithing techniques.

Since blacksmithing involves mastering and becoming comfortable with a core of basic concepts and techniques through repeated practice and honing of skills, this manual is designed to provide participants with exposure to and practice in those basic concepts. The first technical session is designed to provide an overview of the major concepts involved and lay the groundwork for the remainder of the program. Each succeeding session requires the use of skills practiced in prior sessions and introduces one to three new techniques. In this manner, it is intended that participants will complete the program with sufficient skills to enable them to understand and maximize the capabilities of local forges in the production of simple agricultural tools; to set up their own small forge facility; and to continue practicing their blacksmithing skills by adapting and modifying them to suit the needs of the communities in which they are working.

* Identifying staff and trainers:

The specific number of staff should depend on the particular training situation. As a minimal requirement, there should be at least one primary technical trainer and one training coordinator for each twelve participants. The primary technical trainer should be an experienced, capable blacksmith with experience working in developing countries. He/she should have skill in making many types of hand tools using available scrap steel and should be comfortable with the principles of non-formal education, adult learning and integrated training. The training coordinator should have a working knowledge of blacksmithing and experience delivering integrated, participatory training programs. He/she should take the primary role in logistical coordination, facilitation, and helping participants assess their progress and evaluate the program.

It would also be beneficial to have an assistant technical trainer that is a native of the country in which the training is being held. The assistant should be an experienced local blacksmith who has had some prior experience working in cross-cultural situations.

* Locating and establishing a site:

The training program should be located in or near an area that has some ongoing metal work activity, and in a place where a supply of scrap steel is available. It should be in a center of commerce where materials can be purchased and transported easily. It is best to choose a site that includes adequate space to set up six or seven working forges. The training should be held in or near an area where local blacksmiths are working. The rental of space in an existing blacksmith shop, vocational school or outbuilding would be ideal.

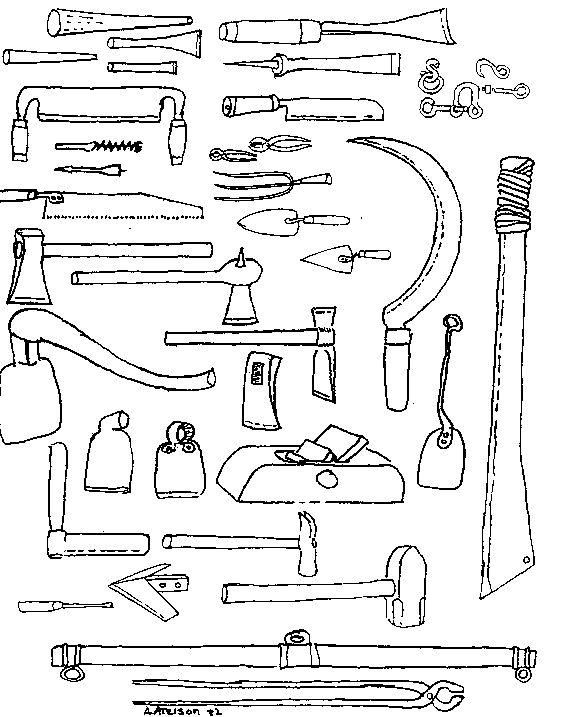

* Gathering necessary resources and materials:

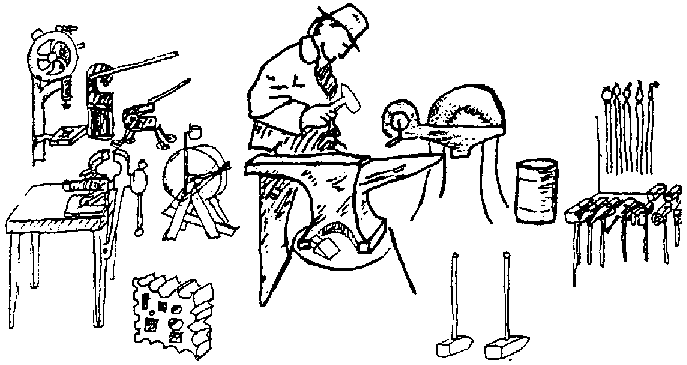

In order for participants to have the opportunity to practice basic blacksmithing skills, it will be necessary to set up a minimum of six (preferably seven) complete forge stations. Ideally, this will require approximately:

7 forges and bellows or blowers

5 anvils and stands or stumps

1 swage block (or equivalent)

3 mounted vices

3 grinders (motorized, electrical if possible)

7 (1,500 gr.) 3-lb. cross-or straight-peen hammers

7 (2,000 gr.) 4-lb. cross-or straight-peen hammers

7 10-lb. cross-or straight-peen hammers

7 pairs large vice grips

7 pairs flat tongs

7 prs. round or V-nose tongs (1/2" - 5/8")

7 prs. pick-up tongs (3/8")

7 hot cuts

7 cold cuts

3 hack saws with 6 extra blades (18 teeth per inch)

7 5-gal. quench buckets

3 quench buckets + lids (filled with recycled motor oil)

7 pieces of abrasive stone (e.g., carborundum)

For the most part, the exact amount of materials necessary will vary with each training situation. Be certain that there are enough materials available before the program begins. It is estimated that there should be on hand approximately:

- 7 files

- fuel to supply forges for five days

- 4 hand-held wire brushes

- supply of flux and brass scrap steel

- variety of leaf springs

- assorted coil springs

- 60' of �". round bar or rebar

- 40' of 3/8" round bar or rebar

- 50' of 5/8" round bar or rebar

- a collection of miscellaneous

- several axles

- bricks

It can be expected that many of the tools and much of the equipment needed for this program will be difficult to obtain in the country where the training is being held. In order to ensure that sufficient resources be available, it is recommended that the trainers bring some of the equipment with them and that they arrive at least two weeks before the training is scheduled to begin. They should make every effort to acquire locally available items, using as guides the materials and equipment lists included here. If some of the suggested items are not available or are not appropriate for use by local blacksmiths, ingenuity should be used to find comparable substitutes.

Although they are not essential to the implementation of the program, a copy of one or both of the following books should be distributed to each participant as texts:

The Modern Blacksmith, by Alexander Weygers

Edge of the Anvil: A Resource Book for the Blacksmith, by Jack Andrews

Conducting the Training

Included here is a list of some considerations that are essential to remember in carrying out the program.

* The training program is designed to provide the basic skills necessary to support local blacksmiths:

Blacksmithing is a centuries-old craft, technology and livelihood. As farming and rural industries develop, the role of the blacksmith in community life takes on its significance. Families need hoes, axes, and machetes. The carpenter, mason and leathermaker all demand specialized tools. Farmers with draft animals ask for prows, cultivators, and hardware for their yokes and harnesses. For the blacksmith in developing countries, the production of these tools and implements involves many complex difficulties, including standardization of equipment, uncontrolled marketing, scarcity of spare parts, shortages of raw materials, and the unavailability of technical information and educational opportunities for refining skills. This program has been designed to provide participants with the basic knowledge and skills necessary to help local blacksmiths work to overcome these difficulties.

* Blacksmithing is a skill which requires much practice to develop:

Although it is explicitly brought out in several sessions, the trainer should continually stress that it is virtually impossible to emerge from a six-day training program as an expert blacksmith.

Blacksmithing is a craft which requires years of hard work, practice, and dedication to develop. Participants should realize that in many cultures, the exclusiveness of the craft has created a mysterious aura of awe and supersition around the metal-working trades.

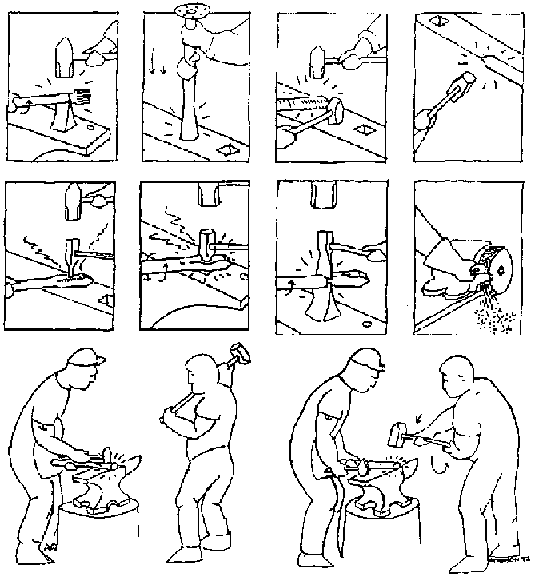

* Safety precautions cannot be over-stressed:

In a blacksmith shop, the opportunity for serious injury is limitless. Extreme care should be taken throughout the program to stress the importance of taking necessary safety precautions. A good general rule is that all metal should be considered too hot to touch until proven otherwise. Potential hazards can be compounded in an environment in which many inexperienced individuals are working in close proximity.

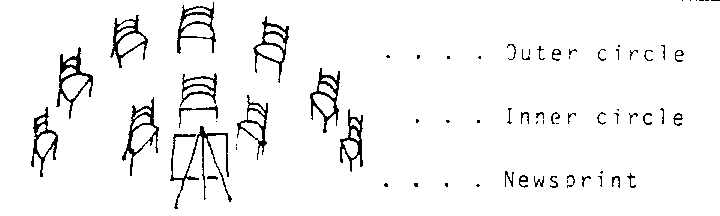

* Working in teams has multiple objectives:

During the program, participants will work in teams at forge stations. This enables them to help one another with many of the practices which require strenuous activity and/or more than one pair of hands. It insures that each participant will have ample opportunity to practice each of the basic techniques demonstrated. And, it provides a forum for practicing the kinds of communication skills necessary to transfer skills to others.

* Most basic Blacksmithing skills can only be acquired through careful observation followed by supervised practice:

In each of the sessions which call for a demonstration of a particular technique, every effort should be made to ensure that participants thoroughly understand the concepts and procedures involved. Write essential procedures on newsprint whenever necessary. Make demonstrations as clear as possible by explaining each procedure carefully and repeating whenever necessary. Following demonstrations, ask participants to review the procedures and to clarify any doubts or confusions which may exist.

* Flexibility, endurance, and patience are key requirements for blacksmithing:

The participants should be advised of the likelihood of spending long, strenuous hours tending their forges and practicing their skills. Blacksmithing does not lend itself well to structured, specified blocks of time. The times suggested to complete each session are approximations. Participants may complete some activities early while running overtime on others.

* The experimental learning cycle is an essential part of training:

It is important that people have the opportunity to learn, examine, generalize about and apply new knowledge. Try to follow the experiential learning loop as often as possible, and encourage the participants to be aware of the process.

* Scheduled breaks between sessions are essential:

Although 10 to 15 minutes is suggested, more time may be needed, depending on the training circumstances.

Using the Manual

One of the keys to the success of the training program lies in thoroughly understanding and effectively using the manual. Included below are some guidelines and explanations designed to help in using the manual.

* The Program Calendar indicates the overall design of the program and recommended sequence of sessions. Use it as a reference in developing a specific schedule which meets the needs of the particular training situation.

* Sessions follow a consistent format. (See the "Sample Session Format" on Page vii for a detailed description,) Be certain to read sessions thoroughly. There are often several purposes to each session; for example, the activities may be designed to meet a technical objective, and at the same time, provide participants with practice in group problem-solving or communication skills. It is important to understand the multi-tiered design of each session before presenting it.

* Attachments follow each session and are usually intended for distribution to the participants. Each attachment is letter-coded as to the session with which it is associated. It is important to make copies of attachments in advance so that they can be distributed during the session.

* The Bibliography includes the reference material, texts, and suggested resources used in developing this program. It can be copied and distributed to participants as the basis for further research in blacksmithing.

SAMPLE SESSION FORMAT

Session 4, Day 1 (Each session is numbered sequentially and coded by day.)

FORGE INTRODUCTION (Title indicates subject area being presented.)

Total Time: (Total Time gives approximate time needed to carry cut the session.)

4 hours

Objectives: (Objectives tell what is expected of participants and what the session should accomplish.)

* To identify and define the basic components of a forge

* To practice using basic blacksmithing tools

* To light, maintain and shut down a forge fire

* To make a forge poker/rake and eye

* To discuss forging practices of local blacksmiths

Resources: (Resources include all attachments and other suggested references.)

* Attachment 4-A, "Color/Heat Chart"

* Attachment 4-8, "Traditional and Rural Forges"

* Andrews, pages 17-21 and 42-46

* Weygers, pages 20-23 and 94-96

Materials: (Materials refers to suggested supplies and tools needed for the session. For some sessions, special tools are listed to provide focus and emphasis.)

Approximately 30-36 feet of � inch mild steel round bar. newsprint, and felt-tip pens

Trainer Notes

Preparation for this session will involve writing on newsprint an outline of the procedures involved in making a forge poker/rake (see Step 6).

Procedures: (Procedures consist of steps to be followed in order to meet objectives. Each step is given an approximate time.)

Step 1. (5 minutes)

Distribute Attachment 4-A, "Color/Heat Chart" and Attachment 4-B, "Traditional and Rural Forges. and briefly explain the session objectives and procedures.

Trainer Notes

Explain that the Attachments will be discussed in more detail later in the session.

Step 2. (10 minutes)

Post and briefly define the list of tools and forge components that will be used in making a forge poker/rake.

Trainer Notes

* Post the following list on newsprint in two columns as indicated below:

(Trainer Notes

* Appear throughout the session and serve to clarify and explain a procedure, provide information and suggest options.)

|

DAY 1 |

DAY 2 |

DAY 3 |

|

|

A.M. |

Session 1: Sharing Perceptions of the Training Program: an Ice-Breaker |

Session 5: Properties of Metals |

Session 9: Eye Hook and Link: Technology Transfer |

|

Session 2: Assessing Group Resources |

Session 6: Forging a Blacksmith's Cold Chisel |

||

|

Session 3: Defining Expectations of the Training Program |

Session 10: Forging Rings |

||

|

P.M. |

Session 4: Forge Introduction |

Session 7: Forging a Blacksmith's Hot Punch |

Session 11: Welding Practices: Forge Brazing |

|

Session 8: Heat Treating |

Session 12: Open Workshop/Mid Program Review |

||

|

DAY 4 |

DAY 5 |

DAY 6 |

|

|

A.M. |

Session 13: Bellows and Forge Design |

Session 16: Forging a Cross-Peen Hammer |

Session 18: Forging Straight Tongs |

|

Session 14: Forging en African Tang-Type Axe |

|||

|

P.M. |

Session 15: Case-Hardened African Field Hoe with Collar |

Session 17: Forging Cutting Tools: The Wrapped-Handle Knife |

Session 19: Program Evaluation |

|

Session 20: Open Workshop/Clean-up |

Total Time: 1 hour, 15 minutes

Objectives:

* To get to know one another and to encourage communication

* To set the climate for active participation during the training program

Resources: Attachment 1-A, "Coat of Arms''

Materials: Pens or pencils

|

Trainer Notes An alternative activity for getting acquainted goes as follows: * Convene the group in the blacksmith workshop area. * Ask participants to browse around for a moment and find a tool or object which they would like to make, and which symbolizes something about their - personality/character - work - background - aspirations - etc. * The trainer should also choose an appropriate object. * When everyone has made a selection and has had a few moments to reflect, introduce yourself and explain why you selected your object (using humor to help create a relaxed climate). * Then, moving around the shop, have the participants introduce themselves and share their reasons for selecting their particular tool. |

Procedures:

Step 1. (5 minutes)

Distribute copies of Attachment 1A, "Coat of Arms" and explain the exercise.

|

Trainer Notes * Explain that the object of the exercise is to draw a symbolic "coat of arms" which will help us begin to get acquainted or find out something new about each other. * Explain that the participants will draw a symbol or picture in each of the corresponding spaces on the coat of arms that answers one of a series of questions. |

Step 2. (15 minutes)

Referring to the list in the Trainer Notes below, read each question in order, allowing time for people to draw their symbol before moving to the next question.

|

Trainer Notes * Suggested questions: - How do you feel right now? - What were you doing a week ago today? - What do you hope to get out of this training? - What can you offer this training? * Draw your-own "coat of arms" while the group does theirs. |

Step 3. (5 minutes)

After everyone has finished drawing his/her coat of arms, share your coat of arms by explaining the meaning of each of your four drawings.

|

Trainer Notes Encourage an open climate by explaining your drawings in a relaxed and humorous manner. Also, make your presentation brief to set the pace of the activity. |

Step 4. (30-45 minutes) Have each participant explain the meaning of his/her coat of arms.

Step 5. (5 minutes) After all of the drawings have been presented, facilitate a brief discussion of some of the similarities and differences which seem to exist in the group.

Attachment 1-A

Total Time: 1 hour, 30 minutes

Objectives:

* To identify the skills, knowledge, and experience of participants and trainers

* To discuss ways in which the group's skills and knowledge can be used in this program

Materials: Newsprint and felt-tip pens.

Procedures: Step 1. (5 minutes) Review the objectives and procedures For the session.

Step 2. (5 minutes)

Ask the participants to briefly discuss the value of a group resource assessment.

|

Trainer Notes Draw on the participants' experiences in working with artisans in small-scale development projects. |

Step 3 (10 minutes)

Have the group brainstorm a list of interview questions which could help assess the participants'

skills, knowledge and experience.

|

Trainer Notes * To provide focus during the brainstorm, post the key points to be included in the interview: skills, knowledge. * The resulting questions should be consolidated or pared down so that the list does not exceed 4-5 open-ended questions the will stimulate conversation. * In this session, the emphasis is not only on those skills, etc. which relate directly to Blacksmithing, but on any resources one might have which would help the group. |

Step 4. (5 minutes)

Explain the interview format.

* If the training group is a small one, an option to the written reports would be to have the pairs interview each other, reconvene the groups, and ask each participant to describe his/her partner.

Step 5. (60 minutes)

Have the participants carry out the interview procedure.

Step 6. (5 minutes)

Reconvene the group and facilitate a short discussion of the participants' overall impressions of the resources that exist within the group.

|

Trainer Notes During the discussion, point out a number of the identified skills which are particularly useful/necessary in blacksmithing (e.g., carpentry, construction, auto/farm mechanics, welding). |

Total Time: 1 hour, 15 minutes

Objectives:

* To review the schedule and content of the program

* To define and clarify expectations that the participants have of the training program

* To compare and contrast individual expectations with those of the program.

Resources:

* Introduction to the Manual, pp. i-ii.

* "Conducting the Training," pp. iv-vi, from the Introduction to the Manual.

* Training Schedule

Materials: Newsprint and felt-tip pens

Procedures:

Step 1. (5 minutes)

Briefly outline the session's objectives and activities.

Step 2. (20 minutes)

Distribute copies of the three resources. Have the participants read them carefully, then ask for questions, clarifications or discussion.

|

Trainer Notes Explain that the training philosophy and methodology and the section on conducting the training provide an orientation to the basic program goals and guidelines, while the training schedule presents a day-by-day description of the training. |

Step 3. (15 minutes) Have the participants form small groups and discuss their expectations of the program. Ask each group to list on newsprint and post their three most important expectations.

|

Trainer Notes * As they develop their lists, participants should be encouraged to consider their needs and desires, as well as constraints in scheduling and programming. * If the training group is small, you may wish to remain together and make a master list of participants' expectations. |

Step 4. (25 minutes)

Reconvene the large group and review each expectation for clarity, understanding, and feasibility.

|

Trainer Notes * Identify which expectations will be met directly, those that will be touched upon, those which could be addressed with some schedule changes, and those, given the practical limitations of the program, which may not be met. * Wherever possible, point out specific sessions in the Training Schedule which deal directly with the group's expectations. |

Step 5. (10 minutes)

Conclude the session by facilitating a discussion centered around the following questions:

* Were any of your expectations changed by this activity?

* Is there anything that you have heard about the training program that has not been discussed?

* Do you think the program will meet your needs?

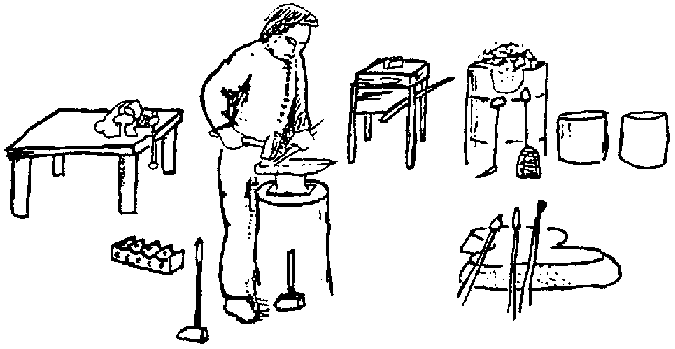

Total Time: 4 hours

Objectives:

* To identify and define the basic components of a forge

* To practice using basic blacksmithing tools

* To light, maintain and shut down a forge fire

* To make a forge poker/rake and eye

* To discuss forging practices of local blacksmiths

Resources:

* Attachment 4-A, "Color/Heat Chart"

* Attachment 4-B, "Traditional and Rural Forges"

* Andrews, pages 17-21 and 42-46

* Weygers, pages 20-23 and 94-96

Materials: Approximately 30-36 feet of � inch mild steel round bar, newsprint, and felt-tip pens

|

Trainer Notes Preparation for this session will involve writing on newsprint an outline of the procedures involved in making a forge poker/rake (see Step 6). |

Procedures:

Step 1. (5 minutes)

Distribute Attachment 4-A, "Color/Heat Chart" and Attachment 4-B, "Traditional and Rural Forges" and briefly explain the session objectives and procedures.

|

Trainer Notes Explain that the Attachments will be discussed in more detail later in the session. |

Step 2. (10 minutes)

Post and briefly define the list of tools and forge components that will be used in making a forge poker/rake.

|

Trainer Notes * Post the following list on newsprint in two columns as indicated below: Forge Components Stand Hearth Firebox and Cleanout Blower Chimney and Hood Quench Bucket Charcoal Forge Tools Anvil and Stand Firetools: Poker/Rake, Shovel Sprinkler * Stimulate discussion by asking participants to look around the demonstration forge area and point out each of the items listed. * Ask participants to explain the importance of the positioning of each of the various forge components. |

Step 3. (10 minutes)

Ask participants to discuss and define the function of each item on the posted list. .

|

Trainer Notes * Have participants explain the relationship between each item on the list and the following basic functions: - fire maintenance - smoke removal - clinker removal - ash removal - positioning of work during heating |

Step 4. (10 minutes)

Demonstrate the proper techniques for lighting a forge.

|

Trainer Notes * During the demonstration, it is important to explain the following: - essential safety precautions - type of fuel used - alternative fuels (i.e., coal or propane) - proper use of bellows or blower - proper building and banking of fire - allowing forge bowl to heat |

Step 5. (15 minutes)

Have the participants form work teams of two and light the forges at each of their work stations.

|

Trainer Notes Circulate among the stations and provide assistance whenever necessary. |

Step 6. (10 minutes)

Reconvene the group and briefly outline the procedures involved in making a forge poker/rake.

|

Trainer Notes * Post on newsprint the following outline: - position cutting plate on anvil - cold cut 3' length of �" round bar - place material in fire - bring material to proper heat for mild steel - hammer - bend an eye - flatten end |

Step 7. (25 minutes)

Demonstrate the procedures and techniques involved in making a forge poker/rake.

|

Trainer Notes * Remind participants of the importance of carefully observing each step in the process and taking note of any procedures which may appear confusing or too fast. * To the extent possible, as the work progresses, provide brief explanations of each essential technique and point out transitions from one step to the next by referring participants to the posted outline. |

Step 8. (20 minutes)

Using the posted outline as a guide, ask participants to review and explain the techniques which they observed.

|

Trainer Notes * Remind participants of the demonstration format discussed earlier in the day (see Session 3, "Defining Expectations: An Introduction to Training") and stress that it is important to begin to sharpen their observation skills. * In reviewing the heating of mild steel to the proper temperature, refer participants to Attachment 4-A, "Color/Heat Chart" and explain that this chart will be used later as a guide in hardening steel. * Before proceeding to the next step, it is important to be certain that all the participants understand each of the techniques demonstrated as well as the necessary safety precautions involved in handling the hot metal. * Encourage participants to ask questions and seek clarifications. * If necessary, repeat some or all of the techniques until participants are satisfied that they are ready to begin work at their stations. |

Step 9. (65 minutes)

Have participants return to their work stations and make a forge poker/rake.

* It can be expected that a few of the work teams will finish their pokers in 15-20 minutes. If this occurs, encourage teams to make another poker/rake such that each participant has the opportunity to practice and become comfortable with the techniques involved.

Step 10. (15 minutes)

As each team finishes their poker/rake, have them shut down their fires.

|

Trainer Notes * Each team will be completing their work at slightly different times. Briefly explain and demonstrate the proper procedures for shutting down a fire to the first team that finishes. Ask that they provide assistance to the next team that finishes. Continue in this manner such that each team has the opportunity to help another shut down a fire. |

Step 11. (20 minutes)

Reconvene the group and ask participants to identify and discuss any difficulties which they experienced during the forging activity.

|

Trainer Notes * Stimulate discussion by asking how each difficulty was resolved. * Explain that the basic techniques used in bending and forming the eye of the poker/rake will be used in Session 9 on Day 3 to make eye hooks and links and ask participants to identify examples of potential uses for eye hooks and links. |

Step 12. (15 minutes)

Ask participants to discuss how the techniques used in this activity compare with techniques that they have seen used by local blacksmiths in their work sites.

|

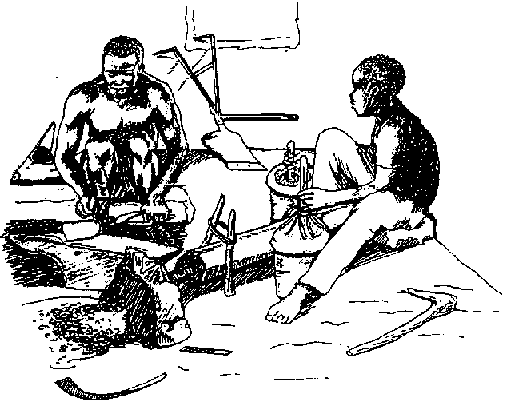

Trainer Notes * Refer participants to Attachment 4-B, "Traditional and Rural Forges" and stimulate discussion by asking: - How are the tools and forges used by local blacksmiths different from those used here in the training? Why? - Are the techniques used by local blacksmiths more efficient? Less efficient? How? - What are some cultural and economic factors which determine the techniques used by local blacksmiths? |

Step 13. (20 minutes)

Conclude by asking participants to summarize the basic blacksmithing techniques used during the session.

|

Trainer Notes * Some important points to include in the summary are: - fire building - fire maintenance - air flow control - safety precautions - heating steel - color/temperature ratio - drawing out - spreading/peening - making eyes/links - bending metal - proper use of tools - local blacksmithing techniques - fire shut-down - uses of eyes and links * Explain that the basic techniques and tools introduced during this session will provide a framework upon which to build throughout the training program. |

Attachment 4-A

COLOR/HEAT CHART

|

F� |

Heat Colors |

C� |

|

2500 |

white |

1371 |

|

2400 |

light yellow |

1316 |

|

2300 |

1260 |

|

|

2200 |

yellow |

1204 |

|

2100 |

1149 |

|

|

2000 |

yellow orange |

1093 |

|

1900 |

1038 |

|

|

1800 |

light orange |

982 |

|

1700 |

927 |

|

|

1600 |

medium orange |

871 |

|

1500 |

816 |

|

|

1400 |

medium cherry |

760 |

|

1300 |

704 |

|

|

1200 |

dark cherry |

649 |

|

1100 |

593 |

|

|

1000 |

black heat |

538 |

|

F� |

Color Patina |

|

610 |

light blue |

|

590 |

dark blue |

|

570 |

blue |

|

550 |

dark purple |

|

540 |

purple |

|

520 |

brownish purple (peacock) |

|

510 |

dark brown |

|

500 |

bronze |

|

490 |

dark straw |

|

470 |

light straw |

|

450 |

yellow |

|

440 |

light yellow |

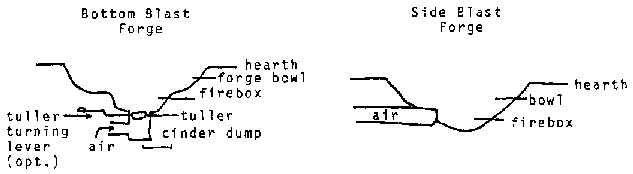

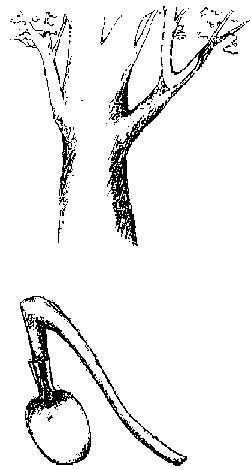

Attachment 4-B

TRADITIONAL AND RURAL FORGES

Total Time: 1 hour

Objectives:

* To determine the type/grade of available junk steel

* To discuss the properties and characteristics of various grades of steel

* To identify potential uses of available steel

Resources:

* Attachment 5-A, "Identifying and Testing Scrap Metal"

* Andrews, "Carbon Content of Steel for Different Uses," page 127

* Weygers, "Steel for Blacksmith," page 15

Materials:

A variety of junk steel salvaged from wrecked autos and rail cars; e.g., leaf springs, coil springs,

axles, torsion bars, linkage rods, push rods, valves, rail tie, plate, rail spikes, rail section, side or

bed plate from rail car, sill from rail car, etc.

Procedures:

Step 1. (10 minutes)

Explain the objectives and distribute Attachment 5-A, "Identifying and Testing Scrap Metal." Ask the group to read it.

Step 2. (15 minutes)

Select a piece of junk steel and demonstrate how to identify its type and properties.

|

Trainer Notes * Note and discuss the significance of color, weight, surface finish, sound when dropped, and flexibility. * Have the participants discuss the junk items' previous use and postulate the type of steel of which it is made. * Describe and perform the spark and quench tests to further verify the type of steel. * Based on the reading, the tests, and the previous use of the item, ask the group to discuss its composition (% of carbon) and qualities (hardness and elasticity). * Explain how heating, forging, and heat treating affect the characteristics of different steels. * Discuss the advantages and disadvantages of the three types of steel. |

Step 3. (15 minutes)

Have participants divide into four groups and select, identify, and describe the properties of an item of junk steel.

|

Trainer Notes * Explain that the groups should follow the same identification procedure as done by the trainer until they are fairly certain of the type of steel. * Stress that not all of the testing methods necessarily have to be used. * Assist groups who may be having difficulty. |

Step 4. (10 minutes)

Reconvene the groups and have them report on their junk item.

|

Trainer Notes If a group's conclusion is inaccurate, discuss their identification process in order to pinpoint where they went wrong. |

Step 5. (10 minutes)

Have participants examine the chart on Page 4 of the Attachment and identify potential uses of the scrap items listed.

|

Trainer Notes * Ask the group to focus on those items most available in their areas. * Explain that the chart can serve as a resource in the future for identifying possible sources of material. |

Attachment 5-A

IDENTIFYING AND TESTING SCRAP METAL

Identification

A variety of unknown types of steel are encountered when working with scrap metal. Several simple tests exist which the blacksmith may use to identify these unknowns. Because of logistics, it may not be possible to perform all of the tests, but with one or two of these tests and some experience, one can learn to recognize useful metal at a glance.

There are several types of "steel" that (for the most part) we will not be dealing with in the context of these classes. They are: cast steel, cast iron, high alley steels, and stainless steel.

The other common metals found in scrap that we will not deal with are copper and aluminum; we will use brass for brazing.

The types of steel that we are looking for may be divided, for the sake of simplicity, into three categories: low carbon, medium carbon, and high carbon steel. The percentage of carbon present determines the major properties (i.e., hardness, fusibility, toughness). Only the medium and high carbon steel; are temperable.

Low Carbon: contains about .05-.30% carbon and of the three, because of the relative low cost of production, it is used extensively. Some sources of low carbon scrap are car bodies, some types of rebar, old nails, bolts, panels on railroad cars, railroad spikes, some types of angle iron, rolled pipe, some types of wire, nails, straps, hinges, tanks, drums, etc. It is manufactured in rolled bars, and the most common ones are round, flat or square bars of � - 1". It is NOT temperable but may be forge welded.

Medium Carbon: contains roughly .30-.60% carbon. It is a harder material (harder to work and harder to find), and may be tempered. It is the most available temperable scrap metal. Some sources are springs, axles, torsion bars, gearshift bars, shock absorber bars, and, in general, anything that must stand up to a higher degree of stress and strain. It will not bend easily like mild steel. It is also used where tempering is required (e.g., auto/truck axles, auto/rail car springs, leaf springs, steering columns).

High Carbon: contains roughly .60-1.5% carbon, and usually has an alloy present. It is much harder than medium carbon, but is available in scrap sometimes as old pneumatic drill bits, old bulldozer blades, milling cutters, metal saws, cutting dies, threading dies, and files.

Testing

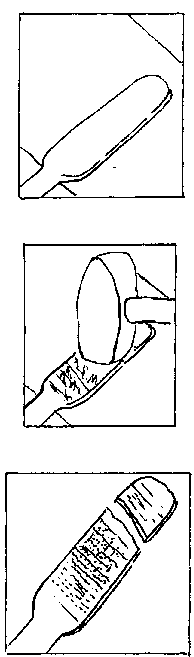

Spark Test: Hold a piece of the material in question against a high-speed grinder and closely observe the sparks given off. Generally, the brighter and more explosive the spark, the greater the carbon content of the steel in question. Try known pieces and study their relationships.

Sound Test: If the piece is small enough, lightly toss it onto a concrete floor or stone. Listen for the sound, and compare the sound to known pieces.

Cold Chisel Test: Using a sharp cold chisel and light blows, attempt to cut the beginning of a curl from the material in question, noticing the following points:

- Does the material cut easily or does it resist?

- If it resists, does it nick the chisel blade?

Again, compare a known material with the piece in question.

File Test: This test is fairly self-explanatory. Using a file, test the surface for hardness. This also reveals the color of unoxidized metal.

Hardening Test: Take the piece in question and heat its tip to light cherry or dark orange and quench it in water. Test it with a file, and note:

- Does the file slide over it like glass?

- Do the teeth bite slightly, or is there no difference between the hardened part and the rest of the piece?

Again, if in question, test against a known piece.

Previous Use: One of the most important clues in determining the type of steel in question (whether tempered or not) is to be found in its previous use. If a piece of steel would have needed to be exceptionally tough, tempered, and/or abrasive-resistant to perform Its function (e.g., torsion bar, spring, pneumatic bit), then we can assume with greater certainty that it is some type of medium to high carbon steel.

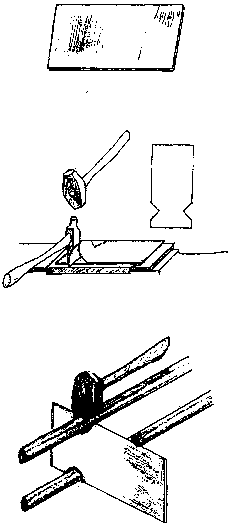

TEMPER TEST

If an untested spring is to be used for tool making, it is advisable and practical to perform the temper test.

Flatten evenly a 4" section.

Perform the water quench (heat reserve method) on the end, quenching before the colors run the entire length of the piece.

Strike with hammer.

Critical color is determined by where the break occurs in relation to the patina. Tools from this spring should then be tempered at the color/temperature prior to the critical color.

SCRAP METAL IDENTIFICATION - A. Atkeison

|

TEST METAL |

COLOR |

SOUND |

BENDING |

MAGNETISM |

SPARK |

FILE |

COLD CHISEL |

PREVIOUS USE (EXAMPLES) |

|

ALUMINUM |

silver, oxidizes white |

high-pitched ringing |

varies |

non-magnetic |

none |

easily & clogs teeth |

easily |

non-ferrous (cans, roofing) |

|

STAINLESS STEEL |

silver, does not oxidize |

tough |

both magnetic. & non-mag. types |

smoothly |

||||

|

COPPER |

soft reddish orange |

bends easily |

||||||

|

CAST IRON |

no ring; thin pieces break when dropped |

brittle, will not bend |

magnetic |

dull red lines |

easily |

chips |

evidence of mold |

|

|

CAST STEEL |

files, but is tougher than cast iron |

evidence of mold |

||||||

|

LOW CARBON STEEL |

easily |

bright reddish, non-explosive |

files |

|||||

|

MED. CARBON STEEL |

very difficult to impossible |

bright, semi-explosive |

files |

|||||

|

HIGH CARBON STEEL |

does not bend |

very bright, explosive |

difficult |

|||||

|

BRASS |

Total Time: 3 hours

Objectives:

* To identify and discuss different types of chisels and steels suitable for making chisels

* To practice uncoiling an automobile spring

* To hot-cut steel

* To make a cold chisel blank

* To use a grinding wheel and practice grinding techniques

Resources:

MacPherson, "The Cold Chisel"

Weygers, pages 45 and 59

Materials: Automobile coil spring, 112" to 5/8" diameter (1� cm) (each team should have one coil spring available at their station), several types of chisels, woodworking, metalworking, stoneworking, etc.

|

Trainer Notes * The chisels distributed in Step 2 should be assembled in advance. * The procedure for making the cold chisel should be prepared on newsprint and ready to post in Step 9. |

Procedures:

Step 1. (5 minutes)

Explain the objectives and outline the procedures.

Step 2. (10 minutes)

Identify and pass out several different types of chisels. Ask participants to try to determine the uses, properties, and forging methods of each one.

|

Trainer Notes * Have the group compare the shape and design of the chisels. * If possible, invite the group to experiment cutting with the chisels. * Discuss the significance of the angle of bevel in cutting edges. * Ask participants to speculate on the type of steel and temper of the various chisels. * Also ask participants to give examples of how they have used one or more of the chisels in their work. * Describe some potential dangers in chisel use, e.g., chipping the blade, striking hand with hammer. |

Step 3. (5 minutes)

Ask the group to refer to the list of scrap metals from the last session and identify which ones would be most suitable for chisel-making.

Step 4. (5 minutes)

Display a cold chisel and ask the participants to explain its properties and uses.

|

Trainer Notes * Refer the group to Session 4 when they used a cold chisel to cut round bar. * Have them discuss other potential uses. * Based on the chisel's function, ask the group to determine its carbon content and temper. |

Step 5. (5 minutes)

Light your forge.

|

Trainer Notes * If coal is used as a fuel, demonstrate how to build a fire using coke remaining from the first fire. * If possible, ask one member of the group to review the steps involved in lighting the forge and have another assist you. |

Step 6. (10 minutes)

Heat and uncoil two linear feet of bar from an automobile spring.

|

Trainer Notes Emphasize to the group: * the correct positioning of the coil spring in the fire * the periodic turning of the spring to prevent burning * the banking of the fire around the spring * the importance of even heating * the proper use and type of tongs for holding the spring |

Step 7. (5 minutes)

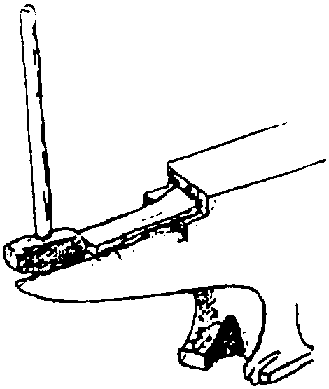

Explain to participants how to determine the length of bar necessary to forge a chisel, to determine the point, and to hot-cut the bar accordingly.

|

Trainer Notes Be sure to point out: * that the spring should be cut most of the way through, then broken, to avoid damaging the hammer on the hardy * that the hardy should be removed from the anvil when finished * safety hazards involved in the process (i.e., hot foot) |

Step 8. (25 minutes)

Have participants go to their assigned stations and ask each team to light the forge, heat and uncoil the available spring, and hot-cut the straightened bar to be used for the chisel.

|

Trainer Notes * To make sure all participants understand the task, ask for a volunteer to repeat the steps. Also, ask if there are any questions before beginning. * During the work, circulate among the stations providing input when necessary and encouraging appropriate hammering and accurate blows. * Be sure to point out any hazardous practices. |

Step 9. (5 minutes)

Reassemble the participants around your station, and explain the steps involved in making a chisel.

|

Trainer Notes * Point out what you expect to accomplish during each heat and mention that they can expect to accomplish less for each heat. * Have the steps outlined and posted on newsprint. * The following steps may be included on the list: - forge stock into eight-sided octagonal bar - forge main bevel - grind cutting edge - chamfer striking end |

Step 10. (10 minutes)

Demonstrate the forging of the cold chisel.

|

Trainer Notes * Refer to each step as you work. * Before you grind the demonstration chisel, point out injuries which can occur from improper grinding practices (i.e., the importance of wearing safety glasses). |

Step 11. (5 minutes)

After the demonstration, review the steps with the group.

|

Trainer Notes * Ask if there are any more questions before the group makes their chisels. |

Step 12. (1 hour, 15 minutes)

Have participants return to their stations and forge, grind and chamfer the cold chisels.

|

Trainer Notes * Again, circulate among the stations, giving input regarding hammering techniques, safety, etc. * Have teams who finish early assist others in the final steps of grinding and chamfering. |

Step 13. (10 minutes)

Reconvene the large group and ask the participants to identify and discuss problems encountered while making their chisels.

Step 14. (5 minutes)

Conclude the session by explaining to the group that they will temper their chisels during Session 8, "Heat Treating."

|

Trainer Notes Briefly mention that the chisels are incomplete until annealed and tempered; two processes which will be discussed in depth during Session 8. |

Total Time: 2 hours

Objectives:

* To identify and discuss different types of punches and their functions

* To make a blacksmith's hot punch

Resources:

* Andrews, page 52.

Materials: 10 - 15 automobile coil springs (6" length and 3/4" to 5/8" in diameter), and a variety of punching tools.

|

Trainer Notes The punching tools distributed in Step 2 should be assembled in advance. They should include at least two types of hand-held blacksmith's hot punch, several cold punches, drifts, mandrels, an awl, nail sets, and center punches. |

Procedures:

Step 1. (5 minutes)

Explain the session objectives and briefly outline the procedures.

Step 2. (10 minutes)

Distribute among the participants a variety of punching tools used by crafts people and discuss their uses and properties.

|

Trainer Notes * Stimulate a discussion of each tool by asking: - What are some potential uses for this punch? - What can be determined regarding the qualities of the steel from which this tool is made? - What are some scrap steels from which this tool could be made? - Which of these punches are used by local crafts people at your work sites? |

Step 3. (10 minutes)

Focus the discussion on the hand-held blacksmith's hot punch and ask participants to identify how it is used.

|

Trainer Notes Some important uses of the punches which should be mentioned include: * piercing sheet metal (cold) * center punching to mark stock * driving out old rivets, shafts, etc * hot punching * drifting (enlarging) holes |

Step 4. (10 minutes)

Briefly explain the procedures involved in making a blacksmith's hot punch.

|

Trainer Notes * Be brief in your explanation and be sure to mention the importance of making the hot punch long enough to allow holding it while maintaining a safe distance from the heat of the piece being punched. * Point out and explain the parallels which exist between the procedures for making a hot punch and those involved in making a cold chisel. * Explain that the punch blanks will be annealed and tempered in the next session, along with their cold chisels. |

Step 5. (15 minutes)

Demonstrate the techniques involved in making a hot punch.

|

Trainer Notes * Before beginning the demonstration, remind participants that they should observe carefully and note any procedures which appear confusing and may need to be clarified later. * During the demonstration, focus your explanation on identifying transitions from one major step to the next. |

Step 6. (10 minutes)

Have the participants review and explain the procedures and techniques which they observed.

|

Trainer Notes * Before proceeding to the next step in this session, be certain that all the participants have had the opportunity to clarify the procedures such that they are ready to begin working at their stations. |

Step 7. (50 minutes)

Have participants form their work teams and practice making a hot punch.

|

Trainer Notes * Circulate among the groups making suggestions, providing assistance, and pointing out safety precautions and examples of good hammering posture. |

Step 8. (10 minutes)

Reconvene the group and ask participants to discuss and share among themselves any technical difficulties which they encountered and what they did to overcome them.

Total Time: 2 hours

Objectives.

* To define and discuss the terms hardening, annealing, and tempering.

* To anneal steel.

* To temper steel.

* To evaluate the problem-solving techniques used by the work teams.

Resources:

* Attachment 8-A, "Water and Oil Quenching"

* Andrews, pages 49-53

* Weyger, pages 36-37

* Weyger, back cover

Materials: Chisels and punches made during Sessions 6 and 7; a piece of coil spring for demonstration of tempering.

Procedures:

Step 1. (5 minutes)

Explain the session objectives and briefly outline the procedures.

Step 2. (15 minutes)

Distribute Attachment 8-A, "Water and Oil Quenching" and ask participants to define and discuss the terms annealing, hardening and tempering.

|

Trainer Notes * Stimulate discussion by having participants describe common techniques used by local blacksmiths to harden steel. * In defining the terms be certain that the following key points are discussed: - the method of water-quenching in hardening and tempering - the method of oil-quenching in hardening and tempering - the concept of correct hardening temperature - degrees of hardness - the importance of annealing before hardening to relieve built-up stresses * If available, distribute among the participants examples of tools which have been tempered and annealed and have them explain why it is important to harden certain tools. |

Step 3. (20 minutes)

Using a punch and chisel blanks made during the previous sessions, demonstrate the proper techniques involved in annealing and tempering.

|

Trainer Notes * Before beginning the demonstration, briefly describe the procedures to be followed and remind participants to observe carefully. During the demonstration, mention and point out the following: - that annealing is a slow process which can take 20-30 minutes in some cases - that the tempering area should not be windy since this causes scaling - that the fire should be clean and free of clinkers and other debris - that oxidation can be minimized by maintaining a low, steady air blast - that care must be taken not to burn cutting edges while heating the stock - signs and causes of steel stress and over-heating * Following the demonstration, take a few minutes to ask participants to review and clarify the important techniques which they observed. |

Step 4. (45 minutes)

Have the participants go to their work stations and anneal and temper the punches and chisels which they made in Sessions 6 and 7.

|

Trainer Notes Circulate among the teams and provide assistance and guidance whenever necessary. However, it can be assumed that, at this point, the participants have become more comfortable with the forge environment. It is important to begin to limit interventions by the trainer to situations involving potential safety hazards and/or situations in which participants are involved in fruitless pursuits which will prevent successful completion of the task. In this manner, by encouraging as much independent experimentation as possible, the participants are given the opportunity to creatively solve their own problems. |

Step 5. (15 minutes)

Reconvene the group and ask participants to discuss and share among themselves any difficulties which they encountered and what they did to overcome them.

|

Trainer Notes Explain that they will be annealing and tempering other tools during the week to strengthen their skills. |

Step 6. (20 minutes)

Have the participants discuss the problem-solving techniques used in their work teams up to this point.

|

Trainer Notes * Briefly explain that in order to transfer the skills which they acquire during this training, participants will, most likely, be communicating and working cooperatively with a local blacksmith. * Stimulate discussion and dialogue among the participants by asking the following questions: - What are some examples of situations in which it was difficult for your team to work effectively? - What was done to help solve these problems and move on? - What factors served to inhibit effective problem-solving? - What can be done in the future to improve your team's ability to work more effectively and cooperatively? - To what extent does the work team design of this training reflect the situation of working with a local blacksmith at your sites? |

Attachment 8-A

WATER AND OIL QUENCHING

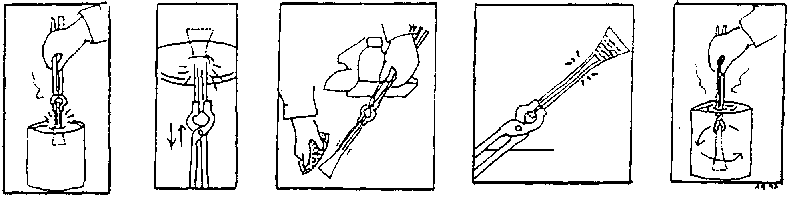

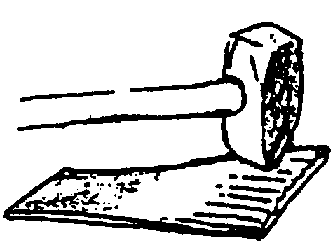

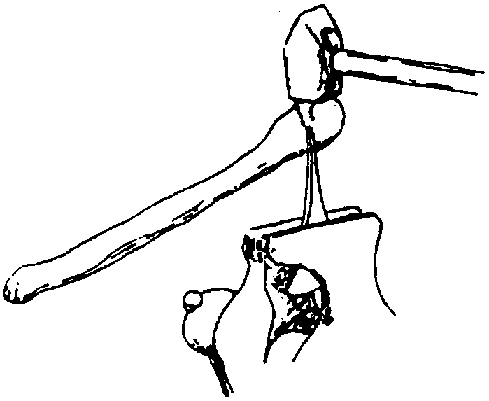

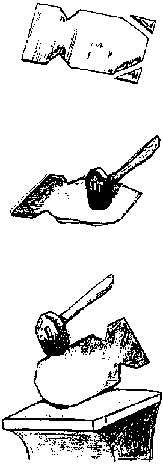

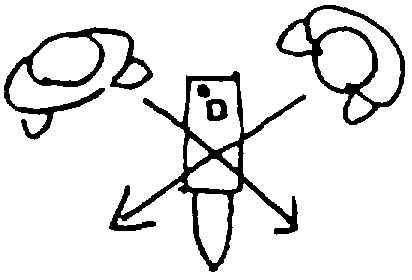

WATER QUENCHING (Heat Reserve Method) - After bringing 3" of the blade end of the piece up to heat:

- quench only the tip (1�") leaving the next 2" or so unquenched.

- move the piece up and down �" in water rapidly to prevent forming a fracture zone where heat contacts water. Maintain this until the heat glow has diminished to a dull cherry.

- Remove the piece from quench and briskly polish the blade surface with an abrasive. Hold the piece with blade upward and observe the color patina as the heat from reserve moves toward the edge. When the desired color reaches the edge, then quench quickly with a swirling motion.

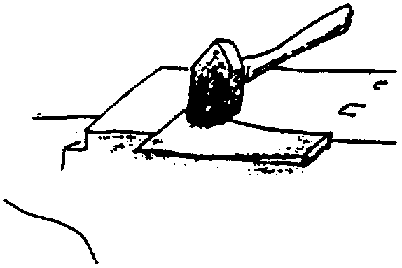

OIL QUENCHING - After bringing 2" of the blade end up to heat:

- with a swirling motion, plunge completely in oil quench bucket, holding the lid nearby in case of an oil flash. If the oil flashes, pull tongs out of the way and snuff fire with tight-fitting lid.

- After the piece has been quenched in oil and is cool to the touch, polish and draw color patina over a propane flame or in a forge, using a metal plate with a hole cut in it (or fire bricks) to direct heat to the piece.

Total Time: 3 hours

Objectives:

* To make an eye hook

* To make a lap joint link

* To practice techniques used in transferring blacksmithing skills to local blacksmiths

Resources:

* Andrews, pages 54-57.

Materials: Newsprint, felt-tip pens, approximately 25-30' of 1/2" coil spring or round bar; 25-30' of 3/8"-5/16" round bar.

|

Trainer Notes Steps 7-9 of this session involve having the participants role-play local blacksmiths. An effective option to this role-play situation would be to invite a few local blacksmiths to observe the demonstrations and ask questions, make comments, etc. |

Procedures:

Step 1. (5 minutes)

Explain the session objectives and briefly outline the procedures.

Step 2. (20 minutes)

Have the participants form their work teams and uncoil and cut two 12" lengths of coil spring.

|

Trainer Notes * Circulate among the teams and offer advice and assistance whenever necessary. * It is important to allow participants to work as independently as possible so that they can practice and sharpen their skills. |

Step 3. (20 minutes)

Reconvene the group and demonstrate the proper techniques and procedures for making an eye hook and lap link.

|

Trainer Notes * Before beginning the demonstration, briefly explain the procedures to be followed and remind participants to observe carefully. * During the demonstration, mention and point out the following important techniques: - calculating materials necessary for eye hook and link - forging a small eye by wrapping it around bar stock - tapering the hook end - bending of hook end to complete eye - forging of lap joints on link stock - bending of stock into link * Following the demonstration, take a few minutes to ask participants to review and clarify the techniques which they observed. |

Step 4. (5 minutes)

Divide the work teams into two groups and explain that Group #1 will make eye hooks while Group #2 will be making lap joint links.

|

Trainer Notes Explain that each team in Group #1 should make one eye hook using one piece of straightened spring (or �" round bar) and that each team in Group #2 should make one lap link using one piece of 3/8" or 5/16" round bar or spring. |

Step 5. (40 minutes)

Have the teams work on their eye hooks or links.

|

Trainer Notes Offer guidance whenever necessary and point out any potentially | I unsafe practices which may occur. |

Step 6. (10 minutes)

Reconvene the group and ask participants to identify and discuss factors which should be considered when planning to communicate technical skills and new forging practices to local blacksmiths.

|

Trainer Notes * Write their responses on posted newsprint * Stimulate discussion and participation by asking: - What kinds of communication aids would be appropriate for local blacksmiths (i.e., models, prototypes, pictures, etc.) - What techniques could be used to stimulate the interest, cooperation, and participation of local blacksmiths? - What techniques could be used to overcome cultural barriers which may exist between local blacksmiths and foreign development workers? - How could local traders and farmers benefit from an availability of rings, hooks, or links? |

Step 7. (5 minutes)

Explain the procedures and roles for the demonstration activity.

|

Trainer Notes * Explain that Group #1 will present a demonstration of the proper procedures for making an eye hook while Group #2 observes and takes the role of local blacksmiths. Then, Group #2 will demonstrate the proper method of making an overlap link while Group #1 observes and role-plays local blacksmiths. * Point out that each demonstration should last approximately 20 minutes and should include time for questions from the observers. |

Step 8. (15 minutes) Have the participants form the two groups and prepare for their demonstrations.

|

Trainer Notes As the groups are working, circulate among them and remind them | of the factors which they identified in Step 6. |

Step 9. (45 minutes)

Have each group present their demonstration.

|

Trainer Notes During each demonstration, it is important that the trainer take the role of a local blacksmith and that he/she set the climate and tone of the role-play situation by asking questions which relate to the list of factors discussed in Step 6. |

Step 19. (15 minutes)

Ask the participants to discuss each demonstration and evaluate its effectiveness as a means of transferring skills to local blacksmiths.

|

Trainer Notes Stimulate discussion by asking: - What aspects of the demonstrations were particularly effective? Why? - How could those aspects of the demonstrations which seemed ineffective be improved? - Which techniques seemed easy to demonstrate? Why? - Which techniques seemed difficult to demonstrate? Why? |

Total Time: 1 hour

Objectives:

* To practice cold-cutting

* To forge rings

Materials: Approximately 20-25' of 3/8"-5/16" mild steel round bar.

Procedures:

Step 1. (5 minutes)

Explain the session objectives and briefly outline the procedures.

|

Trainer Notes Explain that the rings forged during this session will be used to practice brazing in Session 11. |

Step 2. (10 minutes)

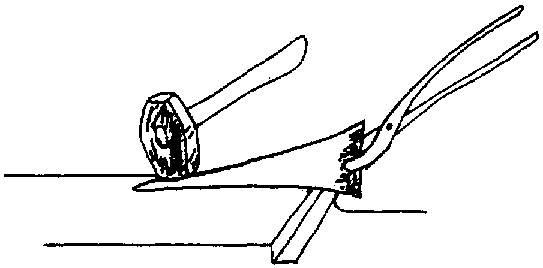

Have the participants divide into their work teams and cold-cut two 10" lengths of 1/2"- round bar.

|

Trainer Notes * As the teams are working, provide assistance when necessary by reminding them of the cold-cutting techniques demonstrated in Session 4. * Again, stress the importance of the proper use of the cold cutter and cutting plate to protect the face of the anvil. |

Step 3. (10 minutes)

Reconvene the group and demonstrate the proper techniques involved in forging a ring and lap.

|

Trainer Notes * During the demonstration, point out the following techniques: - heating of stock to proper color/temperature forming of lap - hammering - use of anvil horn to form ring - determining the proper length of the stock * Have them identify and discuss those techniques which are common to the making of an eye hook or link. |

Step 4 (30 minutes)

Have participants return to their work stations and forge two rings per team.

|

Trainer Notes * Provide assistance and suggestions whenever necessary. * As teams finish forging their rings, have them assist others who may be experiencing difficulty. |

Step 5. (5 minutes)

Reconvene the group and ask participants to discuss and share among themselves any difficulties they experienced and how they overcame them.

Total Time: 1� hours

Objectives:

* To identify and discuss various types of welding processes

* To discuss welding processes used by local blacksmiths

* To forge braze rings

Materials: Forged rings from Session 10, flux, brass rods, an assortment of examples of various types of welds, electric arc, gas forge, flux spoon, etc.

|

Trainer Notes Prior to this session, it will be necessary to assemble and prepare for distribution a collection of examples of various types of welds (see Trainer Notes, Step 2). |

Procedures:

Step 1. (5 minutes)

Briefly explain the session objectives and ask participants to define welding.

* Also, explain that brazing and soldering are welding methods that require the use of a third metal as a binder.

Step 2. (15 minutes)

Distribute examples of various types of welds and ask the participants to describe the methods used in each case and to discuss why one method may be preferable to another.

|

Trainer Notes * Among the examples distributed, be certain to include demonstration samples of forge welding, gas and electric welding, brazing and soldering. * In discussing each type of weld, ask participants who have had experience with welding to: - identify and name the type of weld - describe the process involved and the equipment necessary - give examples of how and where each type is most often used: - discuss fluxes, bonding metals and temperatures - explain why one type of weld may be preferable to another - Describe various kinds of joints (i.e., lap,, but, vee) |

Step 3. (10 minutes)

Ask participants to describe forge welding and brazing processes they have seen local blacksmiths use.

|

Trainer Notes * Some questions to stimulate discussion include: - What similarities/differences exist between processes used by local blacksmiths and those discussed here? - What cultural and/or economic factors influence the welding practices of local blacksmiths? |

Step 4. (10 minutes)

Explain that forge brazing is the type of welding which will be practiced during this session and ask participants to discuss its potential use by local blacksmiths.

|

Trainer Notes * Remind participants of the discussion from the previous steps and have them describe and explain why braze welding could be a viable technique for local blacksmiths. * Ask them to identify some local uses for braze welds (e.g., repairing). |

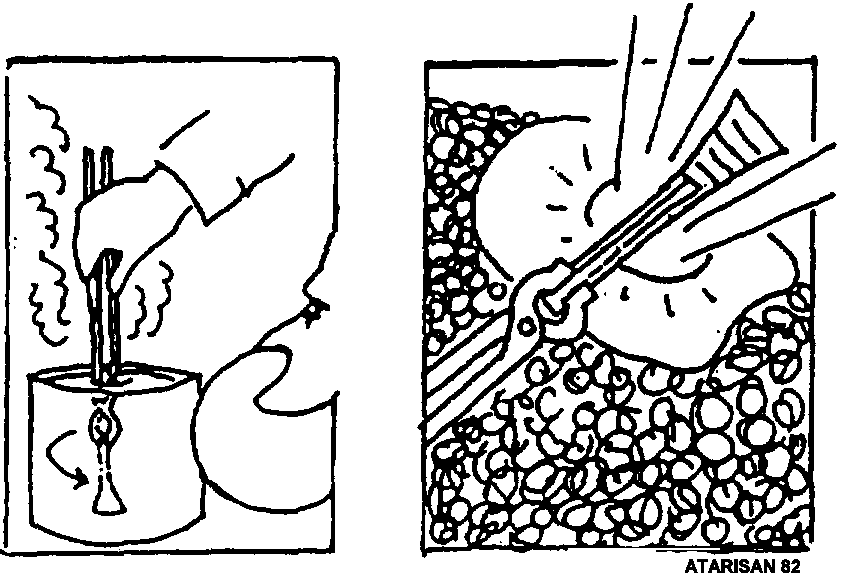

Step 5. (15 minutes)

Demonstrate the procedures involved in braze welding a ring.

|

Trainer Notes * During the demonstration, it is important to point out and explain the following techniques: - cleaning of joint with wire brush after heating and before fluxing - proper control of heat - placement of flux - use of the flux spoon - placement and handling of brass rod - testing the weld for strength - determining when brazing heat has been reached - results of over-heating * Before proceeding to the next step, be certain that participants understand the procedures and techniques involved. |

Step 6. (25 minutes)

Have the participants go to their work stations and forge braze the lap rings that they made in the previous session.

|

Trainer Notes Provide assistance and suggestions whenever necessary. |

Step 7. (10 minutes)

Reconvene the group and have them discuss the brazing activity.

|

Trainer Notes * Have work groups describe any difficulties which they experienced and share ideas about ways to overcome them. * Depending on the amount of time remaining in the session, it may also be useful to demonstrate how forge brazing can be used to repair a broken tool or implement. |

Total Time: 2� hours

Objectives:

* To assess levels of skills acquisition at this point in the training

* To evaluate the effectiveness of the training design and implementation to date

* To work independently at forges

* To finish incompleted projects

* To practice basic blacksmithing skills

Materials: Newsprint, felt-tip pens, assorted scrap steel, round bar, flux, brass rods, etc.

|

Trainer Notes * Prior to this session, it will be necessary to: - write on newsprint a list of the basic blacksmithing techniques practiced up to this point in the training (see Step 2) - assemble an ample supply of the equipment and materials necessary to practice these techniques (see Step 4). |

Procedures:

Step 1. (5 minutes)

Explain the session objectives and outline the procedures.

|

Trainer Notes * Remind participants that this is the mid-point of the training and that it is useful to spend time reflecting upon and evaluating the effectiveness of the program to date. * Explain that participants should take this opportunity to suggest ways in which the program could be improved so as to take better advantage of the days remaining. |

Step 2. (20 minutes)

Ask participants to briefly review and describe the basic blacksmithing techniques which have been practiced up to this point in the training.

|

Trainer Notes * Post on newsprint a list of basic techniques practiced to date, including: - fire building - fire maintenance - safety procedures - heating - hammering - drawing out - cutting (hot and cold) - bending - upsetting - punching - grinding - tempering - measuring - annealing - proper use of tools - brazing * Referring to the posted list, ask the following questions: - With which skills do you feel most comfortable? Why? - Which skills do you feel you would like to practice more? Why? * Explain that these techniques will continue to be used and practiced during the remainder of the program and encourage those participants that are comfortable with certain techniques to offer assistance to others who are not. |

Step 3. (20 minutes)

Ask participants to discuss and evaluate the effectiveness of the program design and implementation to date.

|

Trainer Notes * Stimulate discussion by asking: - Do you feel that the training has been effective in bringing out the issues and complexities involved in working with local blacksmiths? Why? - What training techniques has the trainer used that have been particularly helpful? - What could the trainer do to improve his/her training techniques? - Which sessions have been effective, ineffective - why? - What are some things that the participants could do to improve the effectiveness of the training? * Encourage participants to be specific in their responses. * Record on newsprint some of their suggestions and explain how they can be implemented during the remainder of program. |

Step 4. (1 hour, 45 minutes)

Have participants use the remainder of the day to work independently at their forges, finishing projects and/or practicing techniques with which they may not yet feel comfortable.

|

Trainer Notes * Allow participants the opportunity to finish projects or practice skills and techniques of their choosing. * Circulate among the groups. Help to locate materials. Offer assistance whenever necessary, being careful not to intervene to the point of inhibiting the freedom of experimentation and/or independent problem-solving. * For those participants experiencing particular difficulty with certain techniques, it may be useful to repeat some of the basic demonstrations done earlier in the training. |

Total Time: 50 minutes

Objectives:

* To list and describe design criteria for a forge and bellows

* To evaluate forge and bellows designs

* To discuss the feasibility of introducing new forge and bellows designs to local blacksmiths

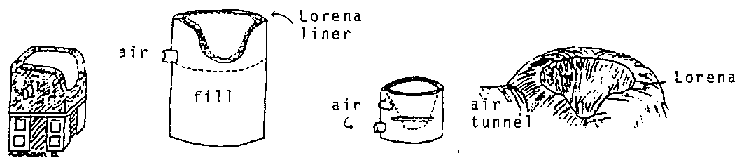

Resources:

* Attachment 13-A, "The Japanese Style Box Blower"

* Attachment 13-B, "How to Build a Blacksmith's Blower"

* Attachment 13-C, "Lorena Forge Design"

* Attachment 13-D, "Forge Pump Designs"

Materials: Newsprint and felt-tip pens

Procedures:

Step 1.

Explain the session objectives and briefly outline the procedures. -

|

Trainer Notes Explain that the design and construction of a bellows and forge will be only briefly discussed during this training since the design of this equipment is extremely relative to and dependent upon the needs, desires and resources of local blacksmiths. |

Step 2.

Have the participants list and describe the design criteria for a bellows and forge.

|

Trainer Notes * Write their responses on posted newsprint according to the example below: Design Criteria Bellows ease of pumping durability control of air blast etc. Forge evenness of heat heat holding capacity low cost etc. * Assist participants in developing the lists by providing a few examples and asking the following questions: - Do the forges and bellows used here at the training meet the criteria? If so, how? - Do the forges and bellows used by local blacksmiths meet these criteria? - If not, how might they be improved? |

Step 4.

Distribute Attachment 13-A, "The Japanese Style Box Blower,'' Attachment 13-D, "How to Build a

Blacksmith's Blower," Attachment 13-C, "Lorena Forge Design," Attachment 13-D, "Forgo Pump Designs," and ask participants to review them.

Step 5.

Have participants discuss the feasibility of introducing new forge or bellows designs to local blacksmiths.

|

Trainer Notes Some questions for discussion include: - Do the designs outlined in the Attachments offer any advantages over traditional types of forges and bellows? How? - Do the new designs meet the criteria developed earlier in the session? - What difficulties might you encounter in attempting to construct one of the new designs at a local blacksmith shop? |

Step 6.

Conclude the session by asking one of the participants to briefly summarize the major factors which should be considered in designing a forge and bellows.

|

Trainer Notes Caution participants against making recommendations regarding forge or bellows innovations without taking time to thoroughly consider the needs, desires and resources of local blacksmiths. |

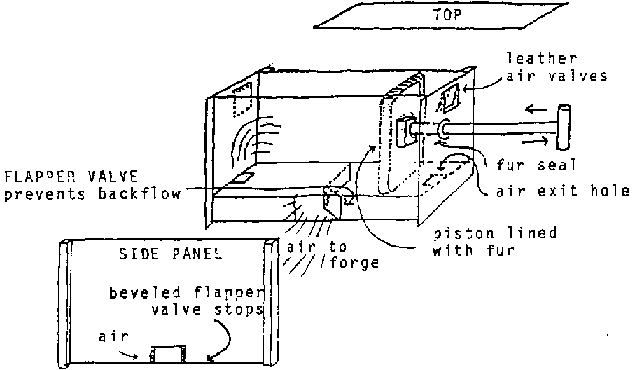

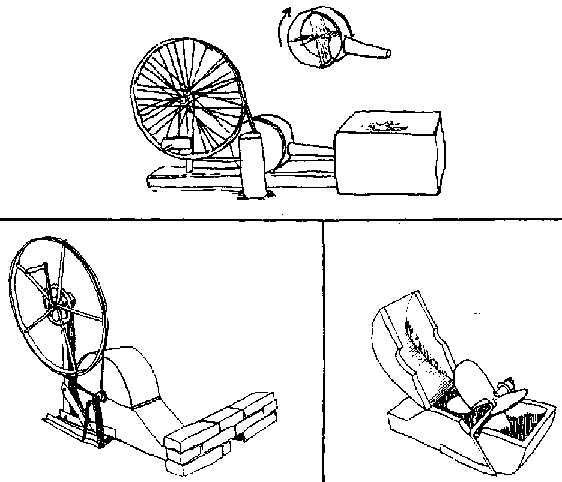

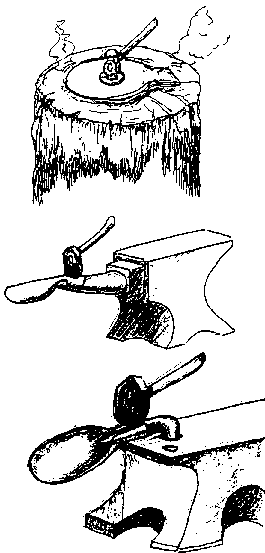

Attachment 13-A

This traditional blower has been used in China and Japan for hundreds of years. It may be constructed in varying sizes. It is used in large lever-powered applications for foundries. Medium sizes (12"x18"x30") are used for forges and small versions are used for home cooking fire blowers.

Blowers may be made from almost any kind of scrap planks, if well-sealed around seams and cracks.

The inner slide chamber should be smooth and preferably waxed or varnished.

The two air inlet valves should be made of fairly heavy leather, and the hinge for the air exit flapper valve should be centered carefully. The bevel-cut on the side should align for a good seal.

It is a good idea to leave the top accessible by not sealing it with glue.

Attachment 13-B

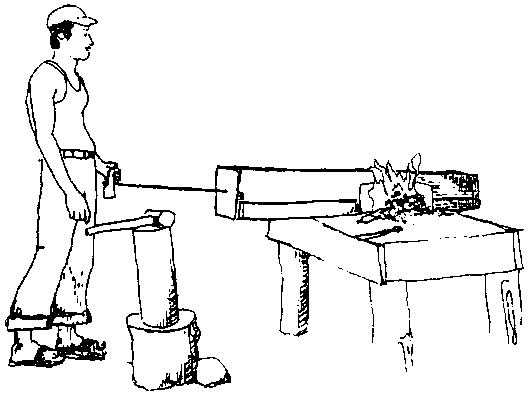

HOW TO BUILD A BLACKSMITH'S BELLOWS

Allen R. Inversin, Appropriate Tech. Development Unit, Lae, Papua New Guinea

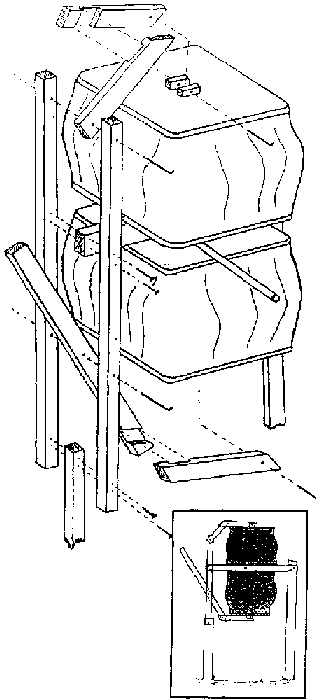

BACKGROUND

The idea for this bellows came from the time-tested, valved, teardrop shaped design which has been in use since about the fourth century. However, as leather is not readily available in Papua New Guinea, a slightly modified version was designed using the inner tube of car tires which can be obtained anywhere in the country. The bellows cost very little to build and require no special skills for construction. It provides a continuous blast of air to the forge, which is more than sufficient to fabricate machetes, chisels, chains, hinges, spikes, etc.

MATERIALS

- Two normal-size car tire inner tubes in good condition and one tube to cut up,

- Four 1-2 cm. boards, each about � m. square, of plywood or narrow boards laminated together.

- Wooden strips around 2x5 cm., totalling about 6 m. in length.

- Used steel pipe, 2-3 cm. in diameter, length 6 m. or more.

- Sheet metal or used steel banding straps.

- Four metal rods about 5 mm. in diameter and 10 cm. long.

- Nails, about 2 and 4 cm. long.

USE OF THE BELLOWS

Although they are easy to use, the bellows should be stroked in a particular way to prevent the user from becoming unduly tired. Two points should be kept in mind:

- Rather than making quick, short strokes, make smooth, full ones starting with the lower board all the way down, and stroke to compress the lower inner tube almost completely.